Welcome! I'm Renee, a recent Mechanical Engineering graduate from Northeastern University in Boston, MA.

I have co-op & internship experience in mechanical design and product development, medical device manufacturing, and medical device quality engineering. I have extracurricular experience in web-based chatbot programming as well as product development engineering and project management.

At these jobs, I have gained technical skills including proper CAD practices, FDM & SLA 3D-printing, laser-cutting, CNC milling, soldering and crimping, test method validation, and mechanical design.

I am currently seeking full-time mechanical design roles beginning Spring 2025!

Check out my highlighted projects below!

Thermoelectric Chamber Tower

Quantitative results of my design work on the new chamber revision

Working on the Tesla's cell qualification test equipment design team, a custom designed thermal chamber tower was needed for battery cell cycling and other testing. As compared to off-the-shelf competitor options, the custom tower was designed to have a more robust temperature control system, higher cell channel density, higher test flexibility, require less maintenance, and do this without using a liquid coolant and at a lower overall cost.

The majority of my time was spent on redesigning the tower from a prototype to production revision for ease, speed, and cost of manufacturing and assembly. Some accomplishments of my redesign are summarized in the table above.

____________________________________________________

Silicone Gasket

Gasket assembled onto cable

Final gasket design: Rev 09

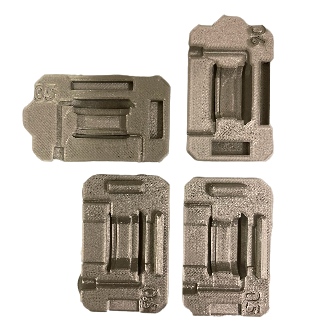

Molds for gaskets

I created this silicone gasket to solve a problem a client was having during my co-op at Fikst Product Development.

This gasket was designed to create a water-tight seal around a thin flex cable to protect the electronics of a custom device being used by the client in a warm, humid incubator. I designed, prototyped, tested, and produced over 25 gaskets and delivered them to the client.

____________________________________________________

Crate Shipping Container

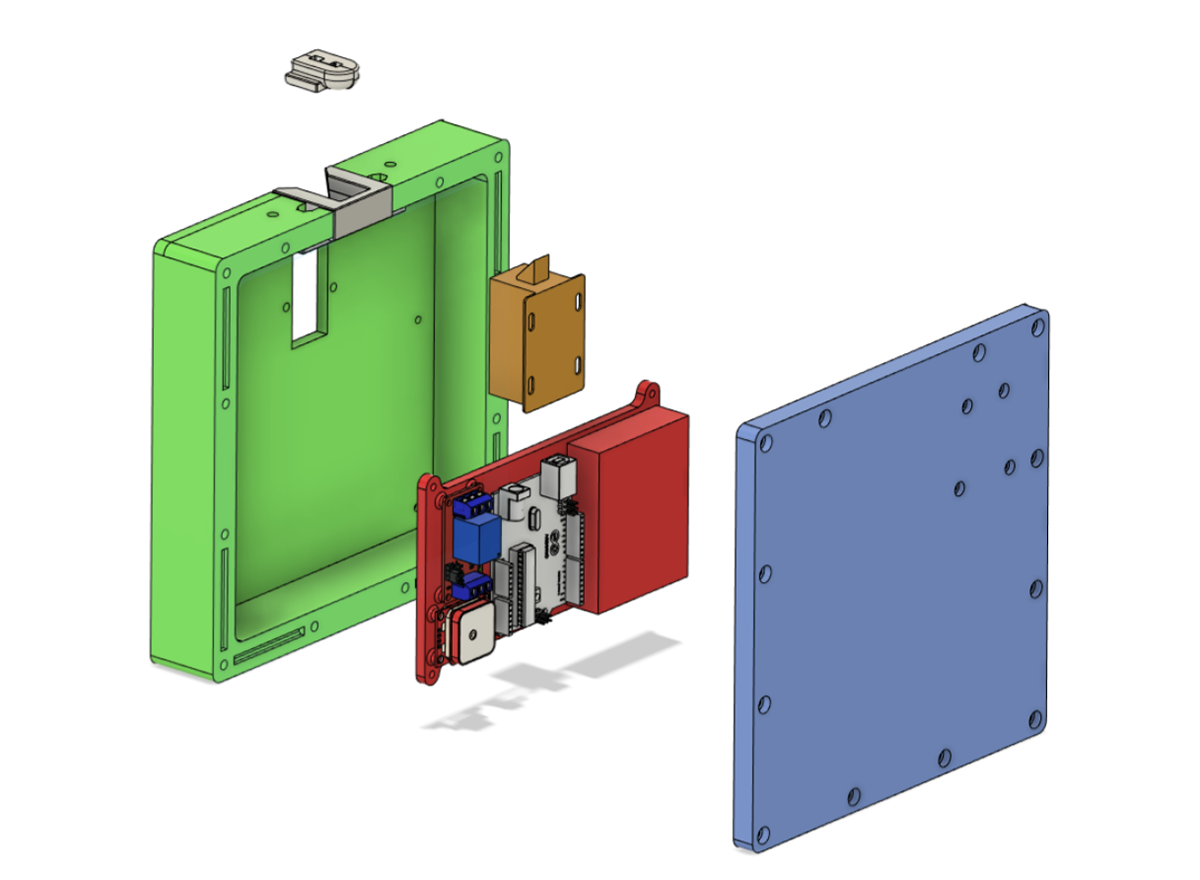

Electronics Enclosure: Design featured two plates which clamped the bag's fabric

Final Prototype: Soft-shell shipping container

Crate was a project I worked on as a build studio engineer at Generate, Northeastern's student-led product development studio.

Crate is a sustainable, lockable, GPS-trackable, soft-shell shipping container that unlocks through the use of RFID. As a team of 7 mechanical and electrical engineers, we designed, tested, and prototyped this device over the course of one semester.

____________________________________________________